Descpription

Falling Film Evaporators with Mechanical Vapour Recompression for Milk and Milk Products

Milk and milk products are high quality foods with defined taste profiles and essential for our daily nutrition. Heat impact negatively influences taste, taste stabilty and the nutrition important components. Also the solubility of powder-milkproducts is negatively influenced by excessive heat.

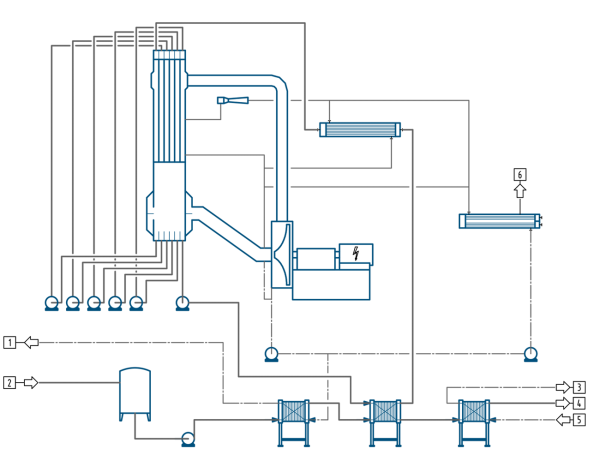

Single effect falling film tube evaporators with multible passes are the perfect match for this evaporation task. The sophisticated M&L design allows evaporation temperatures below 60 °C and minimal product residence times due to single pass process and defined product flow.

Hygenic Design of the apparatusses, the components and the piping system are the basis for optimum product quality and process efficiency.

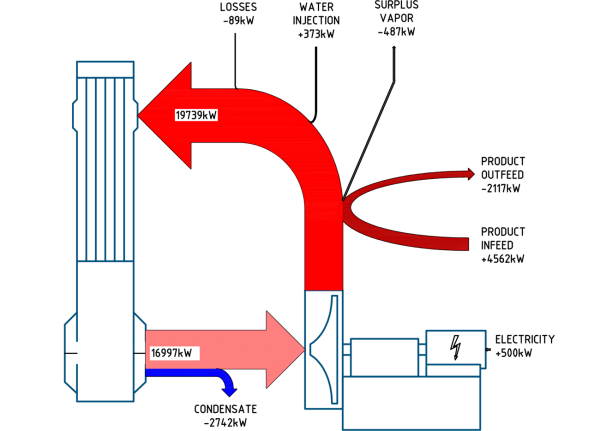

The process is driven by a mechanical vapour recompressor. This is the most efficient heat source available for evaporation processes. M&L is your partner for tayloring this process to your specific need.

Also preheating of the feed flow or pasteutisation of the product before evaporation are a integral part of our systems, fully integrated in the thermal concept of the evaporator and utilizing primary energy best.

Main benefits

High product quality

due to low thermal impact

Lowest possible energy consumption,

down to 10 kWh per ton evaporated water

High efficiency with up to 22 hours production

per day and 2 hours cleaning only

Low maintenance expense

in this way low costs