Descpription

How to increase your output with minimal invest? M&L Engineering has the most economic concept!

Example case study:

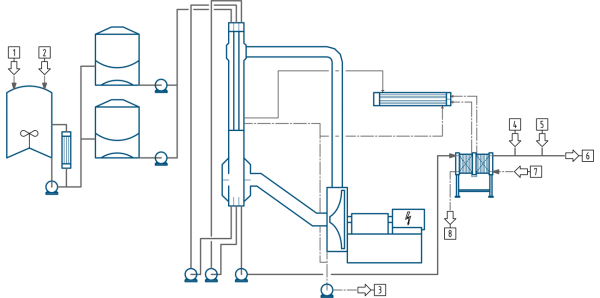

Brewery with limitation in fermentation area plans to increase its output by introducing high gravity brewing. As no change is planned for the mashing/lautering process, the optimal solution to achieve 12 °P to final wort 24 °P is the implementation of an efficient evaporation process.

In the wort kettle the wort is mixed with hop products and heated up by external heat exchanger to maximum 100 °C. During heating up and heat holding no evaporation takes place. Thoroughly mixing is achieved by the pump circulation and agitator if available.

After temperature holding according to specification, the wort is transferred into two whirlpools. The whirlpool is executed redundandly in order to achieve constant flow to the following falling film evaporator. The evaporator is a single effect triple pass evaporator working under vacuum with an evaporation temperature

of 85 °C.

The complete energy for evaporation will be transferred by a mechanical vapour recompressor (MVR). This munit is highly efficiently increasing the pressure of the product vapour to a higher temperature level, allowing utilization of the condensation energy in the vapours for heating of the evaporation process. This is done by an electrical motor driven centrifugal fan. After regenerative cooling, aeration and yeast pitching the wort is ready for fermentation.

Main benefits

Thermal energy only

Electrical consumption

Generation of 1.5 hl brewater

(11 to 80 °C) and 1.185 hl condensate 85 °C per hl final wort, sufficient for mashing and lautering

Evaporation scalable

with evaporator design – no limitation of brewhouse operation to high gravity brewing

Optimized DMS stripping

due to evaporation at 85 °C

Overall energy need 32,000 kJ/hl

final wort for above example