Descpription

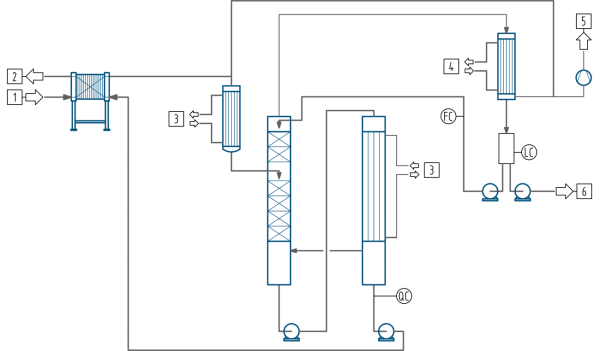

After regenerative prewarming, the beer is decarbonized in a heated falling film prewarmer. Following the beer is fed into a rectification column in the stripper section. There the degassed beer is running against procuct vapours, and an extensive alcohol mass transfer takes place between the vapours and the beer.

From the bottom of the column, the beer is then transferred to the head of a falling film evaporator. In this falling film evaporator the vapours are created for the column operation.

A part of the condensed alcohol vapours (the reflux) is running against the alcohol vapours from the stripping column part, concentrating the vapours up to 75 % alcohol. The alcohol vapours are then condensed by cooling and partialy returned to the column as reflux.

All intert not condensable gasses are sucked out of the process by a liquid ring vaccum pump. An optional aroma recovery is available to recover aroma components from the exhaust inert gasses.

Main benefits

Low temperature process

Alcohol free beer below 0.05 Vol%

Additional aroma recovery

Heating by low temperature water circulation

Alcohol with a concentration of 75 %

Down to 8.2 kWh/hl heating energy

Fit for fill: