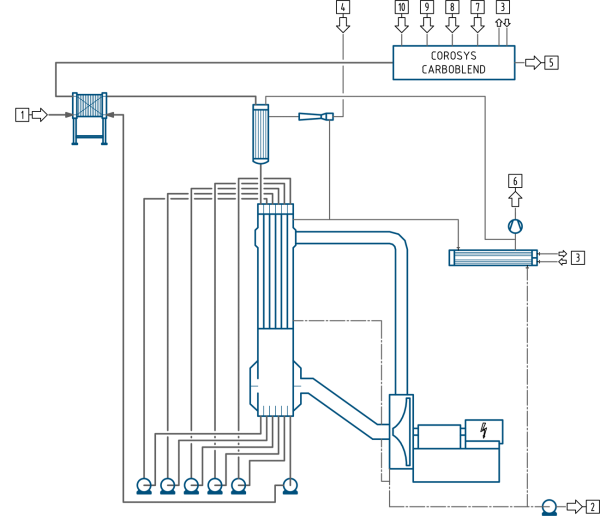

Descpription

After regenerative prewarming, the beer is decarbonized in a thermal vapour recompressor heated falling film prewarmer. Following the beer is fed into a multipass fallfilm evaporator. There the degassed beer is evaporated economically by the mechanical recompressed water/alcohol vapours from the beer.

The vapours are condensing in the shell side of the evaporator and the condenser and the condensate is led to the wastewater system. All intert not condensable gasses are sucked out of the process by a liquid ring vaccum pump.

An optional aroma recovery is available to recover aroma components from the exhaust inert gasses. After regenerative cooling against cold infeed beer, the de-alcolized beer is blended to demand in a corosys carboblender.

Main benefits

Low temperature process

Alcohol free beer

Additional aroma recovery

Heating by mechanical and thermal vapour

Fit for fill:

[ 1 ] beer infeed

[ 2 ] alcohol condensate outfeed

[ 3 ] cooling supply

[ 4 ] steam supply for thermal vapour recompressor

[ 5 ] de-alcoholized beer outfeed

[ 6 ] vacuum exhaust

[ 7 ] degassed water

[ 8 ] beer, wort or other beverage

[ 9 ] CO2

[ 10 ] Iso-Hops or other additives